- Phone:

- 0086-13506565739

- Tel:

- 0086-577-66851569

- E-mail:

- 75156449@qq.com

- Address:

- Songjiadai Industrial Estate,Feiyun Town,Ruian City,Wenzhou,Zhejiang,China

Specification

|

Max.Web width |

340mm |

|

Max.Printing width |

330mm |

|

Max.Unwind Diameter |

1050mm |

|

Max.Rewind Diameter |

1050mm |

|

Max.printing speed |

150m/min |

|

Printing Precision accuracy |

|

|

Rang of printing |

18”-24” |

|

Max.label die cutting speed |

100m/min |

|

Pre –registration |

semi |

|

Material |

All Paper material ,Aluminum material ,some of unsupport film |

|

Thickness of material |

0.038mm—0.35mm |

|

Power |

60KW 50/60HZ |

|

Air Supply |

0.8KPA |

|

80A |

|

|

Machine Weight |

About 8000KG |

|

Dimension |

12500*1450*1500 |

4. Main components

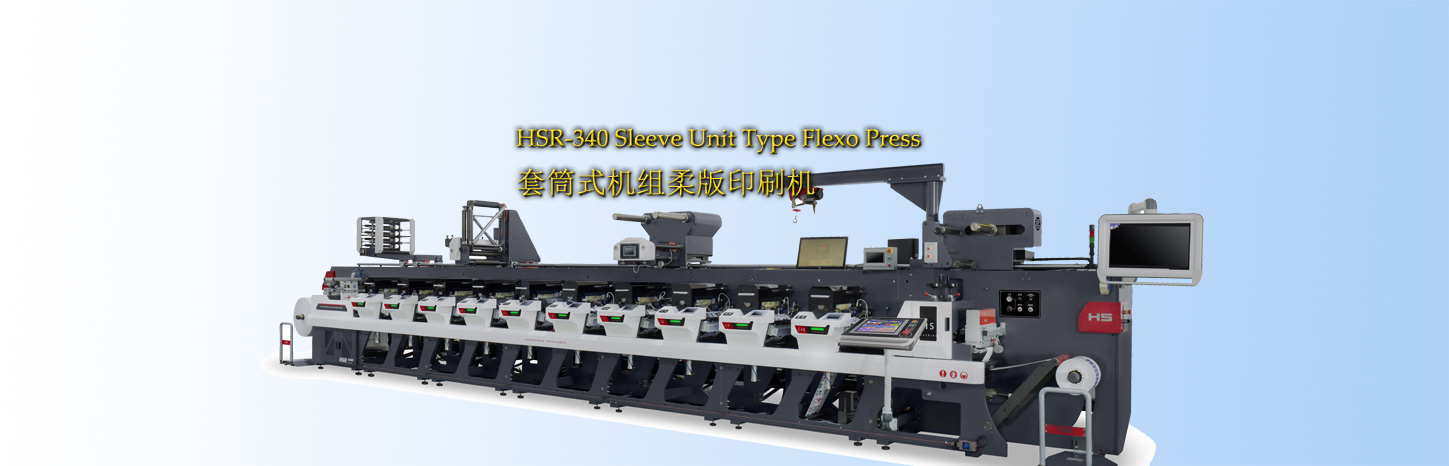

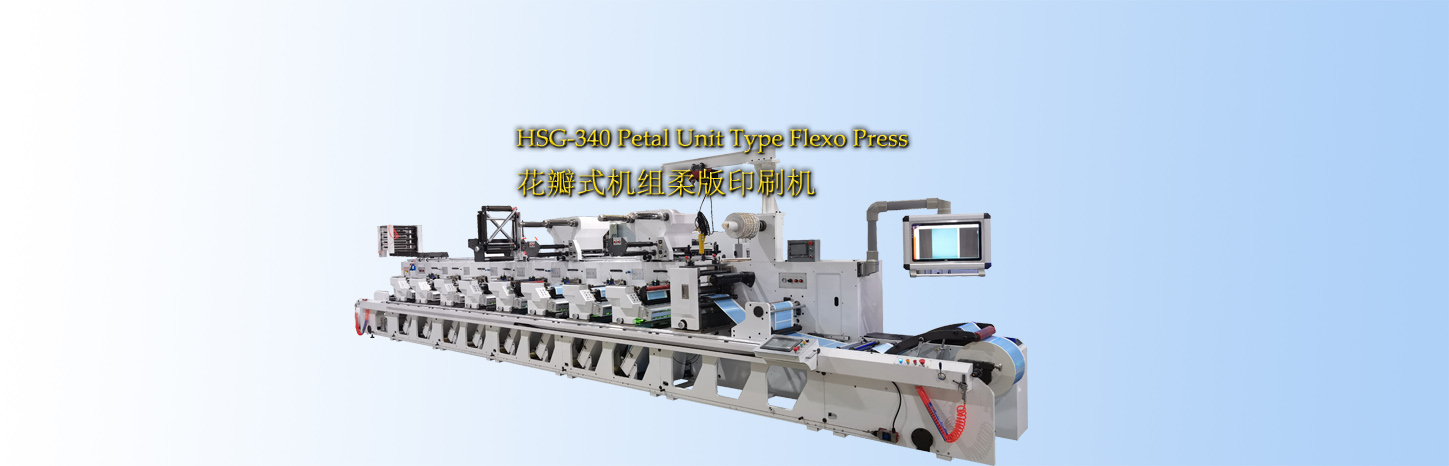

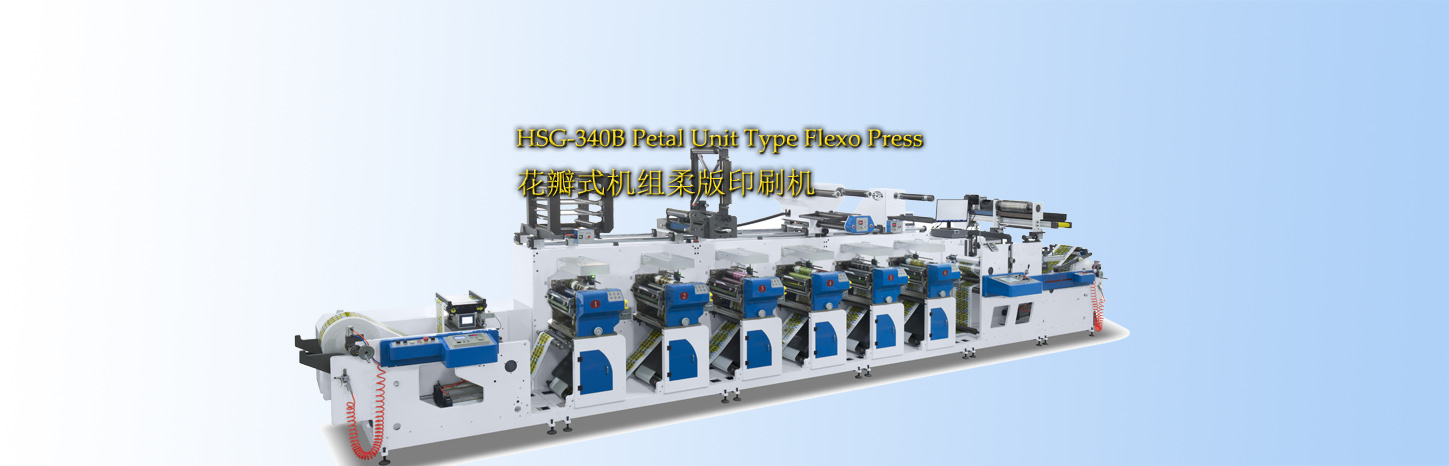

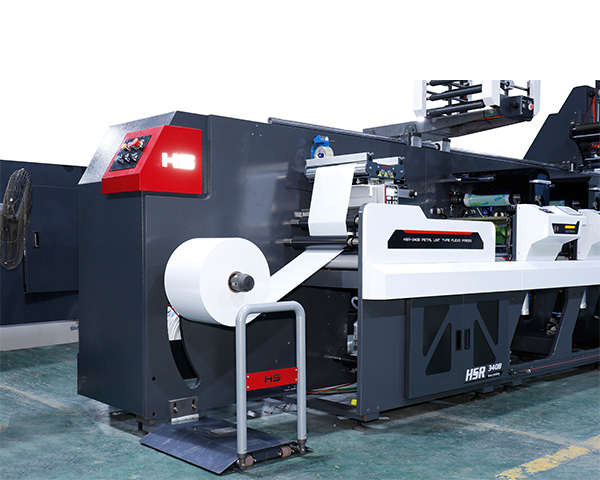

HSG Serial unit flexo presses

Features

The HSG Serial unit flexo presses is our newest machine which aimed to produce high quality label with high speed and IML label function ,This machine compact size and short web path keeps wastage of material ,The full machine adopt all servo motor which keep the tension of film or paper smoothly and stable. It is best machine to print high quality label.

Machine Content

UNWINDING UNIT

? Maximum diameter of unwinding is 1050mm adopt pneumatic cylinder for loading and unloading

? Air expanding shaft for 3 " held by two pcs of Iron arm

? Electronic tension control with load cell feed back for accurate tension control and Magnetic power (Merobel Brand French make)

? Paper cutting platform for pneumatic clamping paper

? Electronic Web aligner for accurate alignment of the Web (BST German)

? Pneumatic components adopted by Airtac

? Corona device effectively increases the amount of ink on film (optional)

? Removing static electricity from material surface with electrostatic device(optional)

? Dust removal from the surface of raw material with dust removal device(optional)

SPLICE TABLE (ON WEB GUIDING)

? Pneumatic controls splice table for east splicing and web jointing

? Individual pneumatic controls for each splice bar

? Splice table with cutter support slot

Nipping driver

? Servo driver controls the infeed and out with auto tension for accurate tension of substrate into printing

? The nipping roller works with pneumatic cylinder and PU roller

? Wide range from 10” to 24” of plate roller

? Teflon technology for ink tray which is easy to clean ,ink roller ,impression roller with tolerance as +/- 0.01mm and ceramic anilox

? Quick change the ink tray and pneumatic lock

? Quick lock and unload for plate roller without using tools

? Helical gears for plate roller and ceramic anilox ,etc

? A Auxiliary motor for anilox keeps running while the press stops to avoid drying the ink on the anilox surface especially when we use water base ink

? Surface hard aluminum guide roller

? Special structure of scraping blade ensure the cleaning of the surface of anilox

? Turn bar on the rail can move across the printing units

? monitor on the end of printing unit can inspect the registration of printing (BST)

? The Impression roller is also a Chiller Drum which in order to cool while printing ,that will not make the material shrink.

? 2 ton capacity Chiller with water circulation system

? Beside saving power ,the LED UV which this machine use also have Chiller connection

? Hot air drying with individual heaters and blowers for optimum usage (Optional)

? Delam -Relam Unit with enough roller fo proper control of web during Delam to print up to 4 colors on back of web (gule side)

? Pre-Register system to set the printing cylinders to near registation before start of printing ,

? Lateral position of printing unit fine turning by worm - gear device

Cold Stamping Device optional

? Cold Foil Unit on rail for movable across printing units

? Magnetic power and clutch control the Cold stamping device

? Pneumatic expanding shaft for unwinding and rewinding

? 1/2/3 set of die cutting station according to the requirement

? 2 stations for die cutting and the third one for perforation or sheeting

? total 3 roller die cutting system for die cutting on the front or back side of the web by changing the anvil roller and transfer roller

? A crane assembled near the die cutting station load and unload the magnetic cylinder

Dual label device optional

? Peel and revel/peel and seal label using overlap system after slitting

Matrix rewinding system

? No break type matrix rewind system

? Matrix rewind with motor rewinding unit ,Surface cum center rewinding

? Max. waste rewinding diameter 900mm

? Pneumatic expand air shaft 3”

? A servo driver controls the running of matrix rewinding

Rewinding device

? Maximum diameter 1050mm

? Air expanding shaft for 3 " held by two pcs of Iron arm

? Pneumatic cylinder for loading and unloading

? The output torque of frequency conversion motor can be adjusted according to the rewinding diameter currently to ensure the stability of rewinding tension

? Anti static bar before rewinding to remove any residual static on the web

Configuration

|

|

HSG |

printing unit |

|

Item |

Position |

Brand |

|

1 |

Whole machine control PLC |

Yaskawar /Japan |

|

2 |

Master touch screen |

Weinview /Taiwan |

|

3 |

Control switch |

Schneider /France |

|

4 |

Connecting terminal |

Huatong /China |

|

5 |

Panel switches |

Schneider /France |

|

7 |

Servo motor deceleration box |

Shimpo /Japan |

|

8 |

Motion controller |

Yaskawar /Japan |

|

9 |

All ordinary small motors and gearboxes throughout the machine |

Panasonic /Japan |

|

10 |

All pneumatic and pneumatic control components |

Airtac /Taiwan |

|

11 |

All plain bearings |

SKF or NTN /Japan |

|

13 |

Unwinding tension control and actuator |

Merobel /France |

|

14 |

Web guiding |

BST /German |

|

15 |

Tension |

Merobel /France |